RKI GX-Force Sample Draw 4 Gas Monitor: A Benchmark in Internal Sample Draw Technology

Industrial environments have become increasingly complex, with evolving processes introducing more potential risks involving gas leaks, emissions, or unexpected chemical reactions. If your work applications require a portable and highly versatile industrial gas monitoring system, the RKI GX-Force Sample Draw 4 Gas Monitor might just be what you’re looking for.

Key Features of the RKI GX-Force 4-Gas Monitor

The RKI GX-Force 4-gas monitor can detect the standard confined space gases, including oxygen (O2), carbon monoxide (CO), hydrogen sulfide (H2S), and combustible gases’ lower explosive limits (LEL). However, what sets the GX-Force apart is its two operating modes, which effectively give you multiple gas monitoring solutions in one instrument.

Utilizing the same advanced micro-sensor technologies found in other RKI gas monitors, such as the GX-3R, GX-3R Pro, 04 Series, and Gaswatch 3, the GX-Force is an ideal solution for confined space safety monitoring in its normal operating mode. When switched to its Leak Check mode, the GX-Force utilizes its powerful internal sample pump to investigate potential CO and combustible gas leaks within 100 feet.

Unlike diffusion monitors that rely on natural air movement, the GX-Force actively draws air samples into its advanced sensors. This allows the instrument to detect low gas concentrations and provide quicker response times, which is crucial for both leak detection and confined space monitoring. According to the Occupational Safety and Health Administration (OSHA), “Confined spaces include, but are not limited to, tanks, vessels, silos, storage bins, hoppers, vaults, pits, manholes, tunnels, equipment housings, ductwork, pipelines, etc. (OSHA, n.d.).

Detailed Comparison: GX-Force vs. Leading Competitors

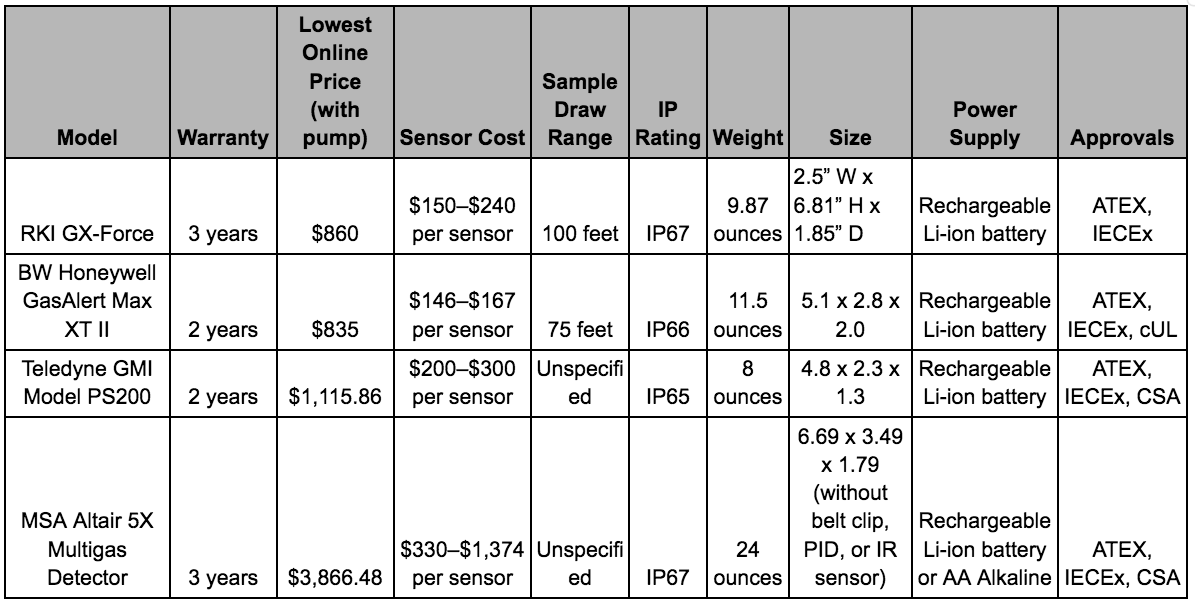

To better understand the RKI GX-Force and why it’s a top consideration when choosing a portable multi-gas detector, let’s take a look at the notable features of comparable confined space monitoring solutions.

- BW Honeywell GasAlert Max XT II: This offering from BW Honeywell is the closest to the GX-Force in terms of price, size, and capabilities. Both devices can monitor up to four atmospheric hazards, have remote sampling capabilities, and combine simple operations with an ergonomic design. If you’re hunting for a versatile and economical multi-gas monitoring solution, you can’t go wrong with either of these powerful instruments.

- Teledyne GMI Model PS200: The PS200 combines ruggedness and advanced technology in a user-friendly, portable multi-gas monitoring package. With a straightforward two-button operation, data logging capabilities, and an impressive runtime of up to 80 hours (when using the low-power LEL sensor), the PS200 makes a compelling case as your next 4-gas monitoring solution.

- MSA Altair 5X Multigas Detector: For more demanding applications, the Altair 5X features arguably the most advanced sensor technology available in a six-gas portable instrument. In addition to monitoring the four most common atmospheric hazards (O2, CO, H2S, and LELs), the Altair 5X can accommodate XCell exotic sulfur dioxide (SO2), nitrogen dioxide (NO2), chlorine gas (CL2), and ammonia (NH3) sensors for expanded monitoring applications. The Altair 5X is a truly powerful instrument and, as such, comes at a much higher price point.

Below are other notable factors to consider:

For standard confined space monitoring, the RKI GX-Force offers value at a price that’s hard to match. As RKI Instruments is a sensor-first company, the GX-Force ensures reliable detection and accurate readings of atmospheric hazards for the utmost peace of mind.

Exploring the Enhanced Safety Features of the GX-Force

The RKI GX-Force is intrinsically safe. This certifies that the instrument is intentionally designed to be incapable of producing heat or spark that can ignite explosive atmospheres. Intrinsic safety ensures that even if a fault occurs, the device will not generate enough energy to ignite the surrounding atmosphere (IECEx, 2006). Additionally, the GX-Force has an IP67 rating for dust and water resistance and passed a three-meter drop test for impact resistance.

Beyond its safe and durable construction, the GX-Force arms users with critical information to guard against atmospheric hazards. Its large display automatically backlights in alarm conditions, allowing users to see all vital information at a glance. These alarm setpoints are fully programmable to specific application requirements. The GX-Force also has audible, visual, and vibrating alarms to ensure users are always aware of potential hazards regardless of visibility or noise levels.

Technical Specifications and Industry Applications

Here’s a rundown of the RKI GX-Force’s primary specs:

- Sensors: The GX-Force uses a catalytic sensor to detect combustible gases (methane (CH4) and hydrogen chloride (HC)) and electrochemical sensors for O2, CO, and H2S.

- Response Times: The GX-Force has the average response times for the following gases: Methane (within 30 seconds), HC (within 40 seconds), O2 (within 20 seconds), CO (within 30 seconds), and H2S (within 30 seconds).

- Sampling Capabilities: The GX-Force has an internal sample pump (with a hydrophobic filter) capable of drawing 0.5 liters of air per minute for analysis within 100 feet.

- Runtime: The GX-Force is powered by a rechargeable lithium-ion battery, capable of a continuous operating time of 30 hours (25 °C, fully charged, no alarm, no backlight).

The GX-Force’s compact, rugged design and user-friendly interface make it suitable for various industries and applications, including personal monitoring, confined space monitoring, petrochemical refineries, utility manholes and tunnels, hazardous waste sites, construction, and fire services.

FAQs: Leveraging the GX-Force for Maximum Safety and Efficiency

- How often should the GX-Force be calibrated?

We recommend calibrating the GX-3R every three months and performing a bump test on the instrument before each use. You can perform a bump test in user mode’s bump item or by applying gas in measuring mode. The instrument doesn’t need to be calibrated unless it doesn’t pass the User Mode bump test or doesn’t respond appropriately.

- How does the internal sample draw pump benefit confined space monitoring?

The internal sample draw pump allows the GX-Force to draw gas samples from remote locations, making it ideal for monitoring confined spaces where direct access is difficult.

- What data logging capabilities does the GX-Force offer?

The GX-Force can log gas readings, alarm events, calibration, bump tests, and other individual data points over time, which can be downloaded and analyzed using external devices. This allows managers to review historical data and identify trends, patterns, and potential hazards to shore up safety controls.

Contact our worker safety supply specialists today for more information about the RKI GX-Force and guidance on choosing the ideal gas monitoring system for your specific requirements. We’re always happy to help.

References:

- IECEx (May 2006). Standards Operated by the IECEx. Retrieved from https://www.iecex.com/publications/standards/

OSHA (n.d.) Confined Spaces. Retrieved from https://www.osha.gov/confined-spaces

Recent Posts

-

Understanding Respirator Replacement Filters

According to the Occupational Health and Safety Administration (OSHA), millions of workers are re …Aug 2nd 2024 -

Explore the RKI GX-3R: The Smallest 4-Gas Monitor | PK Safety

Four-gas monitors have become critical components of workplace safety for industries where exposu …Aug 1st 2024 -

August 12-18 is OSHA’s Safe + Sound Week 2024

Every August, the Occupational Safety and Health Administration (OSHA) spearheads Safe + Sound We …Aug 1st 2024