What Can Be Done To Prevent Falls In The Workplace?

Fall hazards are common in many workplaces. A fall can occur during simple activities like walking on uneven, slippery surface and climbing a ladder, or as a result of complex activities involving work at heights. Fall incidents can also happen when fall protection equipment is misused.

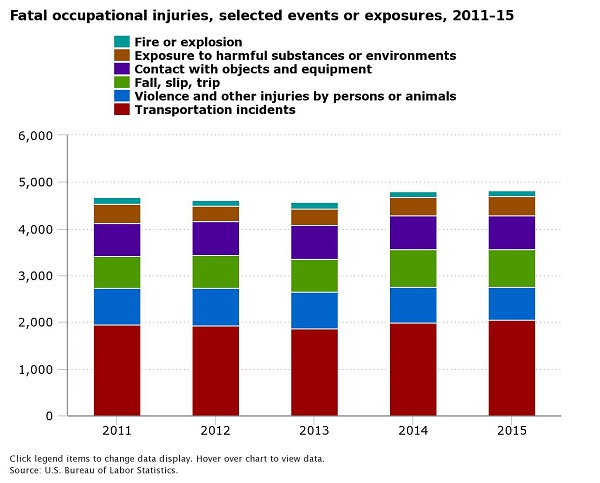

Based on 2014 data published by the Bureau of Labor Statistics, 261,930 workers missed one or more days of work due to injuries from falls. There were 800 work fatalities due to falls, slips or trips in 2015. Falls to a lower level accounted for 81 percent of all fatal falls. Two-fifths of fatal falls occurred from 15 feet or lower. Especially vulnerable are workers in the construction, transportation, healthcare support, cleaning, and maintenance industries. Employees’ compensation and medical costs associated with fall incidents in those industries were estimated at $70 billion a year. To learn more, review the chart below and check out the NATIONAL CENSUS OF FATAL OCCUPATIONAL INJURIES IN 2015 news release.

Making Fall Protection Your #1 Priority

The hierarchy of fall hazard controls includes the elimination of fall hazards (assessment of the workplace and the work processes), prevention of falls (engineering controls), and control of falls (training, PPE). Successful reduction of fall injuries and fatalities requires consistent efforts of employers to plan ahead in order to get the job done safely, to consistently train their employees on the importance of wearing fall protection equipment, and to make sure that their equipment is OSHA-compliant, well-maintained, and appropriate for their specific application.

Remember to involve all employees in the fall hazard assessment. They can provide valuable information about how to eliminate these hazards.

Proper fall protection gear ( harness, lanyard, rope grabs and lifelines, SRLs) and equipment (ladders, nets, guard rails) are required for employees who are working six feet or more above a lower level. These components must be used in conjunction with each other to form a safety system that is capable of providing maximum protection from falls. For example, a boatswain’s chair system is considered to be a single-point adjustable suspended scaffold. Since the suspension system components are not designed to arrest a free fall, a backup fall arrest system, like a fall protection harness, should be used in conjunction with the personal suspension system that would be activated only if the worker experiences a free fall.

A couple of things to be on the lookout for:

- If your equipment is nearing the end of its life, according to manufacturer’s specification sheets, it is a good idea to have it replaced, even if there are no visible defects.

- When a new OSHA regulation is announced or a new work process is introduced, provide adequate training to all the involved employees so that everyone stays updated.

Top 8 Fall Protection Tips from OSHA:

- Identify trip and fall hazards before the project starts.

- Look for the following hazards: unprotected shafts, skylights, stairwells, roof edges, and wall/floor openings.

- Select, wear, and use appropriate fall protection equipment.

- Inspect fall protection equipment for defects before using it.

- Stabilize ladders before climbing.

- Never stand on the top step of a ladder.

- Use handrails to go up/down the stairs.

- Establish good housekeeping practice to keep walkways uncluttered.

If you remember to implement these vital steps for proper fall protection, you can save lives by staying committed to preventing and controlling fall hazards.

You can purchase durable and safe fall protection equipment from pksafety.com. You can also call us at 800-829-9580 to find out more.

References:

OSHA Fall Protection Standards and Regulations:

- Walking-Working Surfaces

- Powered Platforms, Manlifts, and Vehicle-Mounted Work Platforms

- Fall Protection

- Duty to have fall protection

- Fall protection systems criteria and practices

- Training requirements

- Scaffolds

- Helicopters, Hoists, Elevators, and Conveyors

- Steel Erection

- Underground Construction, Caissons, Cofferdams, and Compressed Air

- Safety and Health Regulations for Construction

- CDC: Falls in the Workplace

- OSHA: Preventing Falls

- Workplace Falls

Photo courtesy of OSHA.net

Recent Posts

-

Promoting Safety: National Work Zone Awareness Week is April 15-19, 2024

Each year, the National Work Zone Awareness Week (NWZAW) places the spotlight on the importance o …Apr 11th 2024 -

Understanding 4 Gas Monitors: How They Work & Why They Are Important

In today’s increasingly dynamic industrial landscape, 4 gas monitors have emerged as critical com …Apr 8th 2024 -

April Showers Require Workers to Wear Hi-Vis Safety Rain Gear

While April showers bring May flowers, they also bring challenges, particularly for those working …Apr 1st 2024