ANSI Cut Level Testing Updates: Glove Protection Standards Improve

The American National Standards Institute and the European Union have developed different standards for cut resistant gloves testing and rating criteria, the purpose of which is to facilitate the classification of cut protective clothing. The United States uses ISEA/ANSI standards, while Europe uses EN certification. The standard has no impact on poking or piercing hazards like needle sticks and sharp corners of the broken glass. Two types of cut testing equipment are used to support these standards: a TDM (Tomodynamometer) and a Couptest.

Per OSHA regulations, the final burden of responsibility concerning cut resistance falls on the employer. In order to make an informed decision about the needed apparel performance and cut level protection, it is important to know that these standards and test methods are not interchangeable, which means if you are comparing products, make sure you compare the ones that were tested using the same test method, or at least keep in mind that these two types of testing and certification standards are different.

The recent changes to ANSI cut resistance standards aim to significantly improve the rating of cut protection at a workplace, especially on the higher range of the cut-resistance scale. The increased number of cut levels from five to nine (A1-A9) will provide a more detailed classification and will make it easier for the PPE manufacturer to classify their products. These changes will also allow the employers to speed up the process of finding the best fit for their cut-protection applications.

An overview of the test standards and methods for measuring cut resistance:

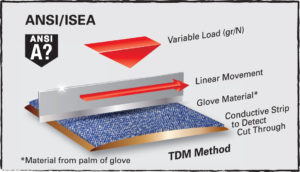

ANSI/ISEA

This test method is now the only one that is recognized by the ANSI/ISEA 105 Handbook. The new ASTM F2992-15 test method allows for only the TDM-100 machine to be used in simulating an accidental cut or slash with a sharp object since this machine generally produces more consistent results. The test measures weight in grams necessary to cut through the material when applied to a razor blade tested over approximately a 1-inch distance. The sample is cut by a straight-edge blade, under load, that moves along a straight path, and is cut five times each at three different loads. The data from these cuts is used to determine the required load to cut through the sample at a specified reference distance. Depending on the results, the glove made with this material will be given a rating between A1 and A9.

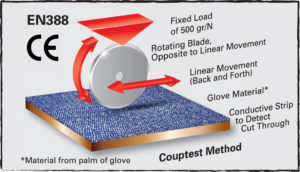

EN 388

The European standard for protective gloves against mechanical hazards uses the Couptest cut machine. A circular blade, under a fixed load of 500 grams, moves back and forth across the sample until cut-through is achieved. A cotton canvas fabric is used as a reference material. The reference material and the test sample are cut until at least 5 results are obtained. The cut resistance is a ratio of the number of cycles needed to cut through the test sample vs. the reference material. The Couptest is not recommended for rating the high cut-resistant material that dulls the blade quickly (for example, glass fiber, para-aramid, etc.) resulting in an inaccurate representation of the protection capability of such materials.

In summary, before continuing with a purchase decision while discussing the product performance levels with sales representatives to determine what product fits best for your needs, make sure you clarify which standard was used to classify the product, and if it is suitable for your particular application and work environment. Also, request a trial sample of the gloves you intend to buy. Ask your employees to test-drive these gloves and to provide you feedback about their performance. Testing a product against worksite hazards at your workplace is vital to the success of your PPE program.

Once the new cut level testing methods are fully implemented across safety glove brands (they are required already as of 2016), it will allow for a higher level of accuracy and a broader range in glove testing capability. This will in turn eliminate the gaps between cut levels that existed under the old classification, and result in achieving a better hand and arm protection and in a decrease in occupational injuries, since it will be easier and faster for manufacturers to classify their products and for the distributors and customers to find a perfect solution for their specific applications.

To learn more about the new classification standards, read our previous blog post: Understanding the New ANSI/ISEA 105 (2016) Hand and Arm Protection Cut Level Classification

If you have questions or need help finding the right hand protection solution, please feel free to call us at 800-829-9580, or visit us online at pksafety.com.

Recent Posts

-

Promoting Safety: National Work Zone Awareness Week is April 15-19, 2024

Each year, the National Work Zone Awareness Week (NWZAW) places the spotlight on the importance o …Apr 11th 2024 -

Understanding 4 Gas Monitors: How They Work & Why They Are Important

In today’s increasingly dynamic industrial landscape, 4 gas monitors have emerged as critical com …Apr 8th 2024 -

April Showers Require Workers to Wear Hi-Vis Safety Rain Gear

While April showers bring May flowers, they also bring challenges, particularly for those working …Apr 1st 2024